He works in the rope access industry and is at home at heights. He's not afraid of hard work and can handle even the most demanding conditions. He's reliable and loves his job. With JACK, work is fun.

Let's take a closer look at him and find out what JACK is really like. For this purpose, we interviewed his father, Martin Horák, a long-time and experienced developer at Singing Rock:

First of all, congratulations on such a beautiful piece of hardware as JACK. It's great that we have a new descender. How much hard work and sleepless nights went into it?

Thanks. We've wanted our own descender at Singing Rock for a long time. A few years ago, we even had one almost ready, but it turned out to have some flaws, it barely passed the tests, and its durability would not have been what we and our customers expected. We stopped sales at the last minute, threw it in the trash, and started all over again to make it better.

What did you focus on when developing JACK, and which part was the most difficult from your point of view?

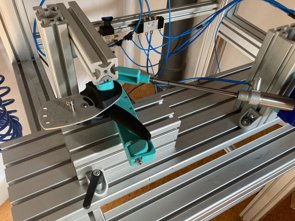

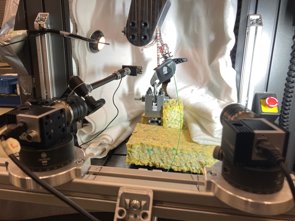

During development, I emphasized maximum simplicity, smooth control, and robustness.br> The worst part of the whole development process is that the functionality of the device depends mainly on the friction between it and the rope, which is almost impossible to describe mathematically, calculate, or simulate on a computer. It is necessary to make a lot of prototypes, test and test.

We can't help but ask, how does JACK differ from the competition in your opinion? Is it unique in any way?

It has a patented design with magnetic locking of the cam, which makes rope installation easier.

Can you highlight the biggest advantages of JACK?

The mentioned maximum simplicity; smooth operation; no need for additional friction up to a load of 200 kg; it automatically locks the rope, allowing the user to fully concentrate on their job.

JACK complies with several different standards. Can you briefly explain what these are and what they relate to?

EN 12841 applies to rope access, which is the activity that most users will perform. In addition to descenders, this standard also covers backup devices and ascenders.

EN 341 is for descenders specifically designed for rescue.

And EN 15151 covers belay and abseiling devices used for recreational activities such as climbing or caving.

Will JACK also meet the North American ANSI and NFPA standards?

We'll see if there is enough demand from customers. For us, it's a completely different world, different legislation, different testing equipment. We may get into it in time.

Before JACK was certified, it certainly underwent a series of tests both in the laboratory and in real-world conditions. How did the tests go?

In real-world conditions, we sent JACKS to selected rope access workers from across the globe to put them through their daily routines in various environments. This gave us valuable feedback on how JACK performs in real working conditions, how users compare it to the competition, and what they would improve if they could. It helped us fine-tune the smallest details before we started mass production and launched JACK on the market.

And one last question: will JACK have any friends in the near future?

We would like to add a new fall arrester and positioning device to complete the hardware family. Stay tuned.

Thanks for the interview. We’re already looking forward to the next new toys!